🔹 Key Features & Benefits

✅ High-Strength & Structural Stability Optimized for superior durability, ensuring enhanced load-bearing capacity and impact resistance.

✅ Smooth Surface Finish Fine-tuned processing delivers uniform texture and precision for various engineering needs.

✅ Corrosion Resistance & Longevity Special coatings and surface treatments enhance durability, minimizing oxidation and wear.

✅ Customizable Thickness & Mechanical Properties Available in multiple gauges and compositions tailored for specific industry requirements.

✅ Energy-Efficient & Sustainable Material Produced using eco-friendly methods, ensuring recyclability and reduced environmental impact.

✅ Exceptional Machinability & Formability Ideal for cutting, bending, stamping, and fabrication across diverse applications.

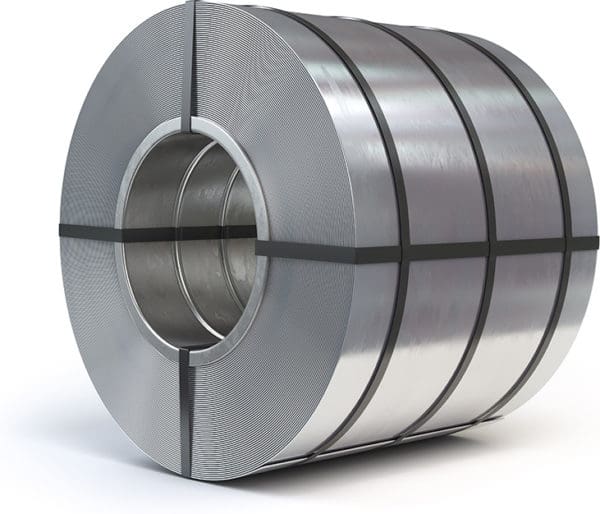

🔹 Cold-Rolled Steel Processing Workflow Overview

1️⃣ Raw Material Selection & Preparation High-grade steel is sourced and prepared for precision rolling and shaping.

2️⃣ Cold-Rolling & Surface Enhancement Advanced rolling techniques refine steel sheets and coils for optimal mechanical properties.

3️⃣ Heat Treatment & Strength Optimization Controlled processing enhances durability and tensile strength.

4️⃣ Quality Control & Final Finishing Completed steel products undergo rigorous testing to meet performance and safety standards.

🔹 Applications of Cold-Rolled Steel

🔹 Automotive & Transportation Industry Essential for vehicle body components, structural reinforcements, and engine parts.

🔹 Construction & Industrial Equipment Supports frameworks, high-precision structures, and machinery production.

🔹 Household Appliances & Consumer Goods Ideal for durable, corrosion-resistant applications in manufacturing and product design.

Cold-Rolled Steel is engineered for precision, strength, and efficiency, making it an indispensable material for industrial, construction, and high-performance applications.

Reviews

There are no reviews yet.