🔹 Key Features & Benefits

✅ High-Purity Copper Composition Ensures optimal electrical and thermal conductivity for industrial applications.

✅ Exceptional Durability & Corrosion Resistance Engineered to withstand environmental exposure, ensuring long-term stability.

✅ Versatile Manufacturing Potential Ideal for casting, machining, and forming into various industrial components.

✅ Optimized for Electrical & Industrial Use Widely utilized in electrical wiring, power generation, and industrial equipment.

✅ Cost-Effective & Sustainable Choice Supports energy-efficient manufacturing with recyclable material properties.

✅ Strict Quality Standards & Testing Each ingot is thoroughly inspected to meet industry regulations and performance benchmarks.

🔹 Production Process Overview

1️⃣ Material Selection & Purification Raw copper undergoes refining to ensure high-purity composition.

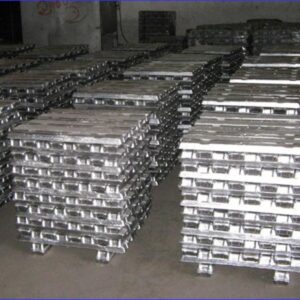

2️⃣ Melting & Casting Copper is melted and formed into ingots with uniform weight and dimensions.

3️⃣ Cooling & Surface Treatment Controlled cooling enhances structural integrity and prevents surface imperfections.

4️⃣ Inspection & Quality Assurance Each ingot is tested for purity, strength, and conductivity standards.

🔹 Applications of Copper Ingots

🔹 Electrical & Power Systems Essential for wiring, transformers, and electrical components.

🔹 Manufacturing & Machinery Used in precision engineering, automotive parts, and heavy industrial equipment.

🔹 Construction & Architectural Uses Supports metal roofing, plumbing systems, and decorative elements.

Copper Ingots are crafted for high performance, adaptability, and sustainability, making them indispensable for industrial professionals and manufacturers.

Reviews

There are no reviews yet.