🔹 Key Features & Benefits

✅ Exceptional Corrosion Resistance Coated with a protective zinc layer to prevent rust and deterioration over time.

✅ High-Strength & Durability Optimized for impact resistance and structural stability in heavy-duty applications.

✅ Versatile Application Range Ideal for use in construction, manufacturing, infrastructure, and automotive industries.

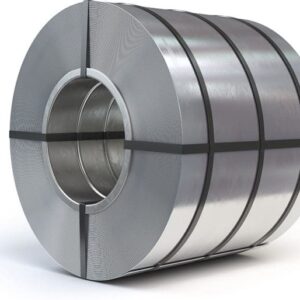

✅ Customizable Thickness & Finishes Available in different gauges and surface treatments, including spangled, matte, and bright coatings.

✅ Energy-Efficient & Sustainable Material Fully recyclable, promoting eco-friendly production and responsible material usage.

✅ Easy Fabrication & Machining Designed for effortless cutting, welding, and shaping in various manufacturing processes.

🔹 Galvanized Steel Processing Workflow Overview

1️⃣ Material Preparation & Cleaning Base steel is treated and cleaned to remove impurities for optimal coating adhesion.

2️⃣ Hot-Dip Galvanization & Zinc Coating Steel is immersed in molten zinc, forming a protective layer against corrosion.

3️⃣ Cooling & Surface Treatment Finished galvanized steel undergoes controlled cooling and final surface refinements.

4️⃣ Quality Inspection & Packaging Processed steel sheets, coils, or structural components are tested for consistency and durability.

🔹 Applications of Galvanized Steel

🔹 Construction & Infrastructure Development Used in roofing, fencing, support beams, and structural frameworks.

🔹 Automotive & Transportation Manufacturing Supports vehicle body components, fuel tanks, and undercarriage protection.

🔹 Industrial & Agricultural Equipment Essential for machinery parts, storage tanks, and corrosion-resistant hardware.

Galvanized Steel is engineered for strength, longevity, and efficiency, making it an essential material for industrial, structural, and high-performance applications.

Reviews

There are no reviews yet.