🔹 Key Features & Benefits

✅ High-Strength Protection Provides a durable shield against environmental factors, including rust, wear, and chemical exposure.

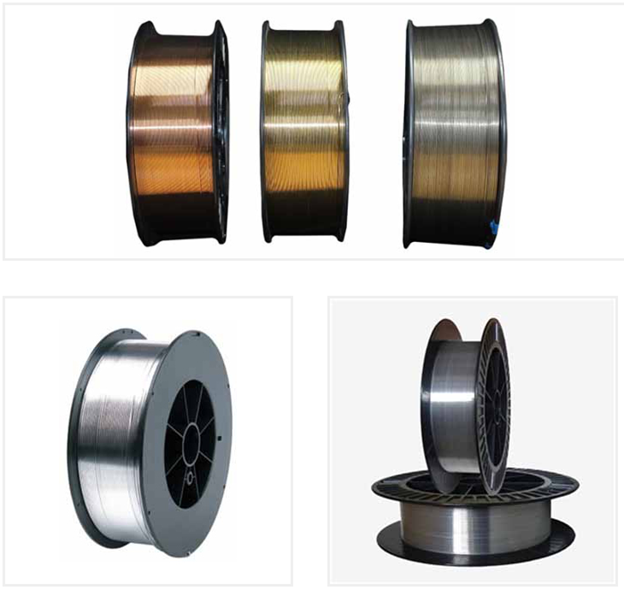

✅ Versatile Application Methods Compatible with various coating techniques, including electroplating, powder coating, and thermal spraying.

✅ Corrosion & Oxidation Resistance Ensures longevity and maintains surface integrity under extreme conditions.

✅ Customizable Formulations Available in multiple compositions, including anti-corrosion, decorative, and high-temperature resistant coatings.

✅ Energy-Efficient & Eco-Friendly Options Developed with low-emission properties and sustainable materials for environmentally responsible use.

✅ Enhanced Surface Finishing Improves texture, appearance, and adhesion for both functional and decorative applications.

🔹 Metal Coating Workflow Overview

1️⃣ Surface Preparation & Cleaning Base metal is treated and cleaned to remove impurities for optimal coating adhesion.

2️⃣ Coating Application & Processing Selected coating technique is applied to enhance durability and functional properties.

3️⃣ Curing & Hardening High-temperature or chemical curing solidifies the protective layer for long-term effectiveness.

4️⃣ Quality Inspection & Final Finishing Completed coated surfaces undergo precision testing for consistency and reliability.

🔹 Applications of Metal Coating Materials

🔹 Industrial Machinery & Equipment Essential for protecting metal surfaces in harsh environments, preventing degradation.

🔹 Automotive & Aerospace Refinishing Enhances resistance to wear, improves aesthetics, and strengthens critical components.

🔹 Architectural & Decorative Coatings Ideal for modern structures, metallic facades, and high-performance building materials.

Metal Coating Materials are engineered for durability, versatility, and efficiency, making them indispensable for industrial, automotive, and architectural applications.

Reviews

There are no reviews yet.