🔹 Key Features & Benefits

✅ High-Purity Composition Ensures consistent material properties for optimal performance in manufacturing and processing.

✅ Versatile Industrial Applications Compatible with multiple industries, including aerospace, automotive, and 3D printing.

✅ Excellent Mechanical & Thermal Properties Optimized for strength, conductivity, and heat resistance in demanding environments.

✅ Customizable Particle Size & Distribution Available in various grain sizes to suit specific processing requirements.

✅ Energy-Efficient & Sustainable Materials Developed with eco-friendly production methods and recyclable components.

✅ Precision Engineering & Surface Enhancement Ideal for coatings, sintering, and specialized metal fabrication.

🔹 Metal Powder Processing Workflow Overview

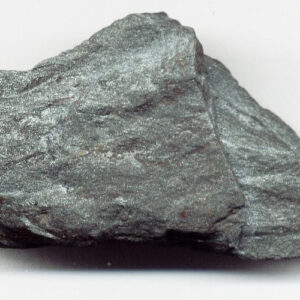

1️⃣ Raw Material Selection & Milling High-quality metals are selected and finely processed into powder form.

2️⃣ Particle Refinement & Classification Powders are sorted by size, composition, and intended application.

3️⃣ Forming & Sintering Process Advanced techniques shape metal powders into complex components or coatings.

4️⃣ Quality Control & Finalization Materials undergo rigorous testing to meet industry standards and performance criteria.

🔹 Applications of Metal Powders

🔹 Additive Manufacturing & 3D Printing Essential for producing intricate components in aerospace, medical, and industrial sectors.

🔹 Metallurgical & Powder Coating Technologies Supports metal sintering, thermal spraying, and advanced surface enhancements.

🔹 Automotive & High-Tech Engineering Used in precision parts manufacturing, conductive materials, and mechanical reinforcement.

Metal Powders are engineered for precision, versatility, and efficiency, making them indispensable materials for cutting-edge industrial applications and high-performance manufacturing.

Reviews

There are no reviews yet.