🔹 Key Features & Benefits

✅ High Durability & Strength Resistant to impact, wear, and moisture, ensuring long-lasting performance.

✅ Flexible & Lightweight Offers excellent adaptability while maintaining easy handling and transportation.

✅ Chemical & Heat Resistance Withstands exposure to industrial chemicals and high temperatures.

✅ Safe & Non-Toxic Ideal for food packaging, medical applications, and household products.

✅ Recyclable & Eco-Friendly Options Available in sustainable variations to support environmental conservation efforts.

✅ Cost-Effective & Multipurpose Optimized for affordability while delivering superior functionality.

🔹 Processing & Manufacturing Workflow

1️⃣ Material Selection & Preparation Choosing high-quality polypropylene formulations to meet industry-specific needs.

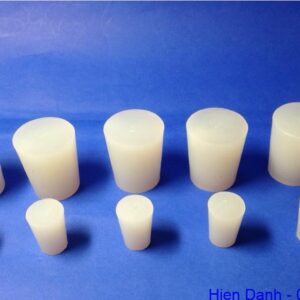

2️⃣ Molding & Shaping Precision engineering ensures uniformity in size, texture, and usability.

3️⃣ Quality Control & Safety Testing Rigorous inspections verify durability, chemical resistance, and safety compliance.

4️⃣ Packaging & Distribution Secure handling guarantees efficient transport and delivery to businesses and consumers.

🔹 Common Applications of PP Plastic

🔹 Packaging & Storage Solutions Used in plastic containers, food trays, and protective wrapping.

🔹 Automotive & Industrial Uses Supports machinery components, automotive parts, and engineering structures.

🔹 Medical & Consumer Applications Essential for medical-grade instruments, textiles, and hygiene products.

PP Plastic (Polypropylene) continues to be a trusted material for modern industries. Balancing durability, efficiency, and sustainability, it remains a top choice across multiple applications.

Reviews

There are no reviews yet.