🔹 Key Features & Benefits

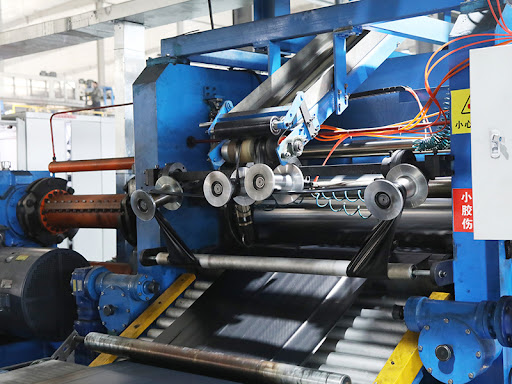

✅ High-Precision Calendering Ensures uniform thickness and consistent surface quality for rubber sheets and coated materials.

✅ Multi-Stage Processing Capability Supports various calendering modes, including smooth finishing, embossing, and reinforcement applications.

✅ Adjustable Pressure & Speed Settings Customizable parameters for different rubber grades and processing requirements.

✅ Heavy-Duty Construction Manufactured with reinforced steel and high-quality rollers to ensure durability and stable operation.

✅ Energy-Efficient Performance Optimized motor and heating systems for reduced power consumption while maintaining maximum output.

✅ Integrated Safety Mechanisms Advanced controls and emergency shutdown features ensure operator protection and system reliability.

🔹 Rubber Processing Workflow Overview

1️⃣ Material Preparation & Feeding Raw rubber materials are positioned for controlled feeding and processing.

2️⃣ Calendering & Thickness Regulation High-pressure rollers compress and shape rubber sheets for uniform consistency.

3️⃣ Surface Enhancement & Finishing Fine adjustments refine the surface texture for specialized applications.

4️⃣ Quality Inspection & Final Processing Completed rubber sheets undergo rigorous quality checks to meet industry standards.

🔹 Applications of Rubber Calendering Machine

🔹 Tire & Automotive Component Manufacturing Ideal for producing rubber sheets used in tires, seals, and automotive parts.

🔹 Industrial Conveyor Belt Production Supports large-scale manufacturing of durable conveyor belts for multiple industries.

🔹 Rubber Coating & Laminating Processes Essential for enhancing strength and flexibility in composite rubber materials.

The Rubber Calendering Machine is engineered for precision, versatility, and efficiency, making it an indispensable tool for rubber processing industries and high-performance manufacturing.

Reviews

There are no reviews yet.